Education Department:

The training unit of Kavian Jaam Glass Industrial Group strives to continuously increase the awareness of its customers regarding this industry.

Therefore, with the participation and cooperation of its specialized and experienced experts in all units, it compiles its trainings regularly. The following written, image and video article is the result of the efforts of our colleagues in the education department.

Definition of glass:

Glass is sand and sand that is melted and turns into a solid and shiny material. Sand, lime, salt and alkali are raw materials that are obtained from a mineral called Trona, which is used in making glass.

Trona in (English: Trona) With the chemical formula Na3H [CO3]2.H2O, it is a group of minerals and is soluble in water. It has a luminescence, sometimes white and blue. It is an abbreviation of a term from the Arabic root (Natron). It boils in acid. Soluble in water Na2O:41.14% CO2:38.94% H2O:19.92% was discovered for the first time in America and in terms of crystal shape: short prismatic, color: gray-yellowish-white, transparency: semi-transparent Fracture: semi-conchoidal – irregular, polished: glassy, face: complete – according to, crystallization system: monoclinic and classified as carbonate, and the source of its formation is salty lakes. Trona is found in Africa, Canada, Türkiye and America.

In fact, glass is a liquid that is very cold and is in a liquid state at a temperature lower than its freezing point.

In general, glass is a transparent object that allows light to pass through it well and the back of it is clearly visible.

In terms of molecular structure, glass has an irregular molecular arrangement in the solid state.

What is construction glass?

These glasses are very resistant and strong due to the different raw materials and of course the different production process they have, and as a result they maintain people’s safety. These are the features that make this glass used in many cases and have a high utility. However, it is better to try to request this glass from high-quality manufacturers so that your safety is well maintained and aesthetic elements are also considered.

Buildings are made of different materials, and glass is one of the main ones. However, the glass used in buildings has many differences with other glasses. Building glass is very different from other glasses in terms of transparency, light absorption, resistance to heat loss or insulation against sound and even impact. For this reason, many applications for this type of glass can be mentioned. These glasses are very different in terms of thickness and color, and in the production process from materials such as sand; Lime, soda, sodium silicate, aluminum and other chemicals are made.

The history of the origin and production of glass

The word glass is derived from Middle Persian and from the word Shishai. This material remained as a luxury tool and the collapses and events that occurred at the end of the Bronze Age stopped the development of glass. The local expansion of glass making methods in South Asia started around 1730 BC.

The oldest natural glass in Iran belongs to the 2nd millennium BC. Samples from the 2nd millennium to 2000 AD include perfume bottles, bangles, statues, bowls, and numerous vessels. In the prehistoric excavations of Chaghazanbil, glass bottles have been found, which indicates the existence of glass in ancient Ilam.

The use of glass in architectural art:

Early humans were able to create many uses for the stone by polishing it. Knife and spear were the first human inventions. But then the volcanic lava rocks attracted their attention. According to the historical evidence, the history of glass can be investigated.

Volcanic lava, most of which was transparent and shiny, became the basis for using stone to make it. Silica, with its crystalline properties, became the primary material of glass. In centuries and ancient times when glass was not widely found and used, glass was used as decorative items and household utensils.

With the existing findings, we know that a type of glass was made ten thousand years before Christ in Egypt or Syria. About 300 years before Christ in Egypt, glassmakers used sand and soda to make glass. Today, in the British Museum, you can see the oldest glass containers that were made in Rome more than 70 years ago and are now kept. Later in the 11th and 12th centuries, Muslims tried to perfect the art of glass making. In the 13th century, Europeans made colored glass to decorate churches. In the early 19th century, glass-making machines were built and the glass-making industry flourished.

Today, due to the progress of science and technology, glass has found a high place and serves people in various uses. This material is not only used in the production of our food dishes, but also in vehicles such as cars, airplanes, etc. Other uses of glass can be mentioned in eyeglass lenses, glassware, doors and windows, construction industries, etc.

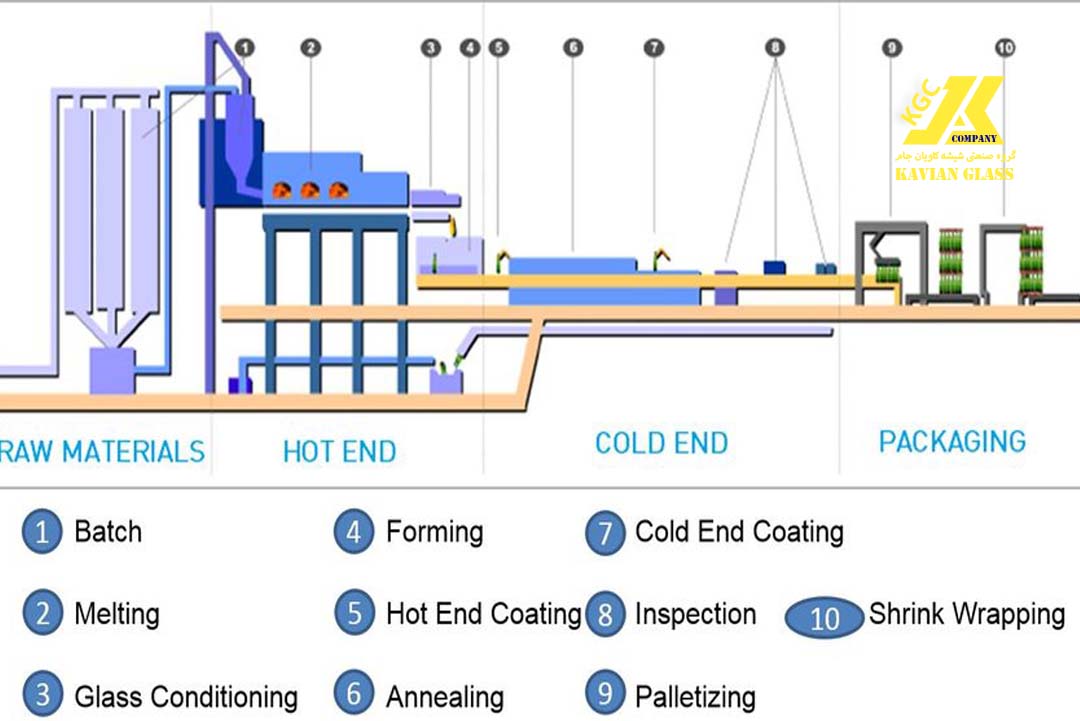

Construction glass manufacturing steps:

- Raw materials for construction:

The main ingredients include silica sand, calcium oxide, magnesium and soda in certain standard amounts and are mixed with each other. Recycled glass is also added to this composition. Using recycled glass reduces energy consumption. The composition of the materials is checked by special devices so that everything reaches the final stage successfully.

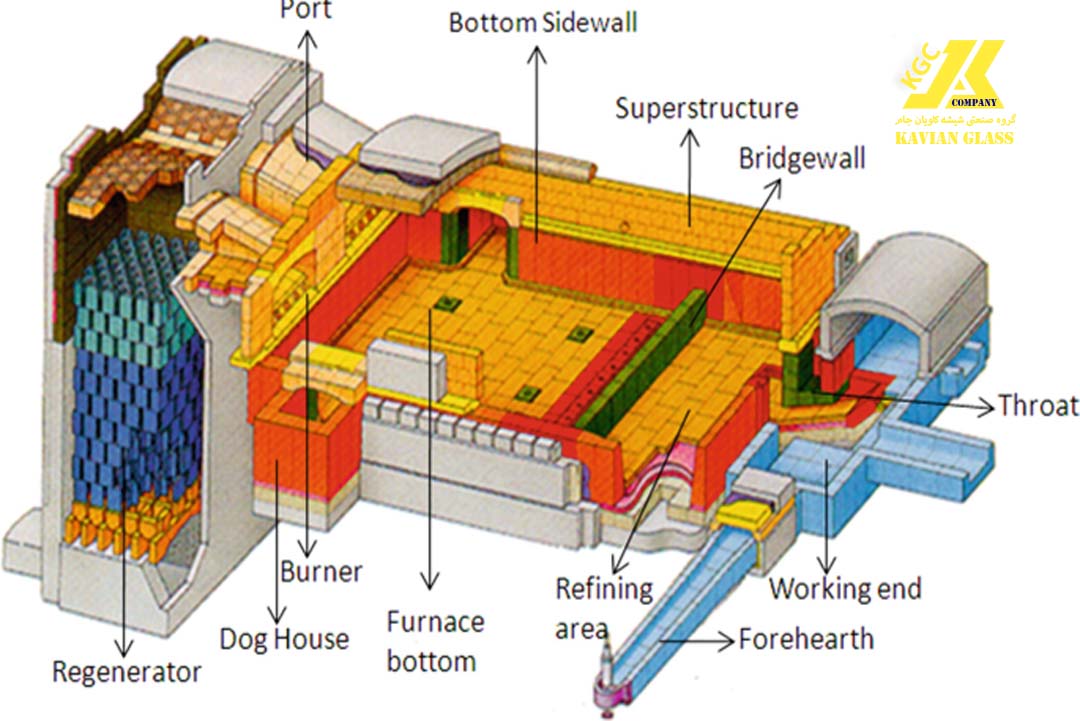

- Melting material:

The combined raw materials are transferred from a cell to a sphere where they are melted at high heat. The temperature in the furnace reaches 1600 degrees Celsius.

- Application of tin molds:

Molten glass, which has a temperature of about 1000 degrees Celsius, is poured onto a mold of molten tin. In this way, glass with a thickness between 5 and 6 mm is produced. With the use of rolling machines, it is possible to increase the thickness of the glass in the range of 1.9 mm to 19 mm. Glass and tin are chemically different and therefore do not stick together.

- Glass cooling stage:

When we remove the glass from the mold, which has a temperature of about 600 degrees, the process of cooling the glass begins. Then it is passed over the glass by means of rollers and its surface is completely smoothed. With the process of annealing the glass, internal stresses are corrected and it is possible to cut and work with it in a predictable way and the smoothness of the glass is guaranteed.

- Quality control and review:

After the cooling phase is over, the glass is subjected to strict quality checks. Then they are cut into sheets of different sizes and prepared for transportation.

Two types of butter are used in industrial factories to produce glass:

1. Bush furnace:

These types of furnaces are capable of producing 2 tons of glass paste and producing glass in a small amount in order to protect the furnace against combustion. Bush furnaces are made of clay and platinum.

2. Tank furnace:

These types of furnaces are made of refractory blocks, and the material enters the furnace from the top of the large tank. The temperature of the ovens is increased and heated with gas or electricity. Water cooling pipes placed around the furnace are used to reduce the temperature of the furnace wall and to prevent it from melting and rotting. After decolorizing and removing the air and gas inside the glass, it is transferred to another furnace with a much lower temperature to reduce its brittleness and make it resistant. By performing some processes, they fix the warp and wave of the glass. After completing the glass production process, the glass is produced and ready to be transferred to the consumer market.

Different stages of production:

Various compounds, stabilizers and raw materials such as silica, boron dioxide, phosphorus pentoxide are used during glass making. In general, the main components of glass are:

sand

lime

Sodium carbonate

1. Raw materials

The float glass process starts with a mixture of raw materials including silica sand, soda ash, limestone and dolomite.

Preparation of raw materials and turning them into powders with grains of 0.1 to 2 mm.

Mixing the materials in the required proportions with 4 to 5% water and transferring the mixture to the furnace to create the chemical composition of the glass.

2. melting

A mixture of about 80% of this mixture and about 20% of glass pellets (internally recycled scrap glass) is fed into a furnace and melted at very high temperatures. After prolonged mixing, the bubbles are released and the molten glass ribbon floats on a bath of liquid tin to effectively facilitate flat, parallel surfaces.

Melting the mixture in a furnace to create a glass paste.

3. Shaping

Tin does not chemically react with glass, and in terms of material density and melting temperature, it is compatible with the glass production process. Inside the tin bath, the thickness of the glass strip is created.

4. Cooling stage:

Along an annealing laher, the temperature of the glass is gradually reduced to near the factory temperature, allowing the material to be cut and stored in sheets of industrial stock.

The characteristics of glass are:

Glass can easily expand and contract against cold and heat.

The transmission of sound in the glass depends on the thickness of the glass and the type of its connection to the window. If the combination of rubber and frame is used, the sound will pass less.

When light shines on the glass, some of it is reflected, some is absorbed, and the rest enters the space. The transmission coefficient is different in different glasses.

The glass thickness ranges from 4 mm to the maximum thickness of 19 mm.

The types of glass are:

Tempered glass

Unbreakable glass

bulletproof glass

Reflective glass

Glass cup

Moshjar glass

Glass block

Reinforced glass

Laminated glass

Safety glasses

Curved glasses

Spider glass

Simple glass

Colored glass

Tempered glass and sand blast

Flute glass

Electric frosted glass

fireproof glass (pyrex)

Insulated or double-glazed glass

Nano or smart glass

Tempered glass:

Tempered glass is one of the most widely used building materials in the field of making and installing glass in interior decoration. Since toughened glass has unique properties such as resistance to impact, heat and even shock holes, many people choose it as an ideal option for use in their buildings, shops and commercial places. They prefer.

Due to the large size of the safety glass, special machines for transporting glass must be used to transport it to the installation site, because these machines have proper safety equipment for transporting this type of glass. Also, reliable and quality fittings should be used to install tempered glass.

During the production of tempered glass, the raw glass is heated again to about 700 degrees Celsius and then cooled suddenly under special and controlled conditions. This action increases the resistance of the glass (about 3 to 5 times) against impact and thermal shocks. If these glasses are broken, they are divided into small and cube-shaped particles, which are not harmful. This type of glass is used in store windows, glass doors and side windows of cars, etc.

Shatterproof glass:

This type of glass consists of two or more layers that are connected by sheets of transparent nylon under heat and pressure. Also, some types of laminated glass are used as sound insulation, heat absorber, transparency reducer and safety glass. When such glasses are broken, the elasticity of nylon prevents the spreading and dispersion of glass particles.

Among the uses of unbreakable glass, it is used in cars and shop windows that sell expensive items. Shatterproof glass may also be made of tempered glass.

Bulletproof glass:

Bulletproof glass is made from the combination of several layers of tempered or unbreakable glass. In this way, they use a type of hard plastic called polycarbonate in the process of layering and between glass layers. For this reason, bulletproof glass is thicker and thicker than ordinary glass. When the bullet hits the glass, its force decreases and it stops in the middle of the glass.

Reflective glass:

In this type of glass, a glass surface is covered with a light and heat reflective coating made of metal or metal oxide with this property. These types of glasses reflect sunlight and are effective in reducing heat and brightness.

If we look at the reflective glass from the outside in the daylight, we will see that the surrounding images will reflect like a mirror, and if we look from the inside to the outside, the glass will be completely transparent. At night, the mentioned vision is the opposite, that is, the glass is transparent from the outside and like a mirror from the inside.

By reflecting sunlight, this glass significantly reduces the heat caused by sunlight. As a result, it saves the costs of construction, operation and maintenance of ventilation and conversion systems.

The glasses that are widely used in architecture are:

glass cup

Tempered glass

Moshjar glass

Reflex glass, etc

glass cup:

This glass has a polished and smooth surface that is produced by passing the dough between two rollers or by passing over molten tin. The dimensions of this type of glasses are out of standard.

When a glass with large dimensions is needed, they use cup glasses. Then they transport it with special machines so that it is not damaged and reaches the installation site safely.

Mojjar glass:

Due to the pattern and roughness of the glass, the light does not pass through it uniformly and does not provide a clear image from the other side of the glass. In the production of this type of glass, in the glass shaping stage, embossed, patterned and shaped rollers are used.

Tempered glass is used in architecture and interior decoration. It is also used in partitions and greenhouse glasses. This type of glass has different designs and shapes and is available in the market.

for example:

Barfi, armbandi, microscopic, French and wire designs, beedy leaves and thousands of other designs

It is also available in thicknesses of 4, 5, 6, 8 and 10 mm.

glass block:

Glass blocks in different types, including simple, patterned, decorative, etc. it’s gonna be built. These glass blocks not only transmit light, but also heat and sound insulation. Their dimensions are usually known: It is 20 x 20, 30 x 30 and 10 cm thick.

These blocks are produced through blow molding, such as bottling through hollow molding or by welding the edges of two semi-circular block pieces and pressing them together. Choosing the right and appropriate color and design of glass blocks and installing them plays a significant role in the beauty of the building’s architecture.

Reinforced glass:

The use of reinforced glass is that in order to prevent the glass from shattering and breaking when hit, a network of steel wires is placed inside it. These wires are located in two layers of glass paste. This type of glass is mostly installed for entrance doors, elevator doors, motor homes, workshops and wherever there is a risk of the glass being crushed and broken.

With the introduction of new glasses that have better performance than wired glass or reinforced glass that have both fireproof and impact-resistant properties, the discussion of the ineffectiveness of wired glass has become much more serious.

Laminated glass:

To prepare this type of glasses, the glasses are glued together using special resin adhesives with high pressure. Factories usually place a layer of patterned plastic between two pieces of glass to make this type of glass patterned.

Laminated glass is more secure than other glasses. Usually, when ordinary glasses break due to impact, they become large and very sharp pieces that have life and financial risks. In that case, laminated glass has a better condition than other glasses when broken.

Laminated glass has three distinct and important features:

They are thermal insulation

Reduce noise pollution

Higher security

The tempered glass does not fall in any way during the impact and they remain on the taluk.

Safety glass:

Safety glass is hard to break and has high resistance against the forces caused by impact, explosion, wind and earthquake. If it breaks, it turns into small pieces that do not have the strength of normal glass and minimize the loss of life and property of the accident.

This type of glass becomes 5 to 6 times more resistant than normal glass after the hardening process. It is difficult and in most cases impossible to make subsequent changes on safety glasses. Therefore, sufficient care should be taken in preparing the required map.

At the same time, during the hardening process, it is possible to bend the product into a cylindrical shape. Of course, in this context, there are limitations regarding the thickness and radius of the circle.

The windows of the entrance doors of the shops are of this type.

Bending glass:

Curved glass is mostly produced in order to realize the ideas of architect engineers and building facade designers. Curved glass is mostly produced in order to realize the ideas of architect engineers and building facade designers.

Creating diversity in space, using unused space and creating harmony and harmony in vision are the unique features of this type of glass.

Spider glass:

In some facades of the building, spider glass is used in such a way that there is no clear frame in the facade of the building. In such cases, special spiders are used according to the required design and the weight of the glass and its height. In this way, very beautiful glass facades are created.

Plain glass:

Plain glass is colorless and available in the market in all three types of 4×4, 4×6 and 6×6.

Colored glass:

This type of glass consists of a plain glass and a colored glass. Of this type of glass, there are only 4 x 4 and 4 x 6 types, and there is no 6 x 6 type due to the high price of 6 mil colored glass.

Sandblast glass:

Sandblasted glass is a type of glass that is used to hide private spaces. This type of frosted glass is mostly used in private places such as bathrooms, bedrooms, lighting devices and even doors. Sandblast glass has the ability to cover the transparency of the glass and prevent the view inside and outside, as a result, everything in these spaces is hidden from others.

Sandblasted glass is, in fact, a type of 10 mil tempered glass with extraordinary properties. This glass with high resistance has become one of the most used and popular products in the construction industry. Since sandblasted glass is easily frosted, it is suitable for places where privacy is required.

Among the places that sandblasted glass can add beauty and security to are the doors of rooms, stores, offices, vip centers, beauty salons, medical centers, server rooms and in short all the places that need privacy. They have, he pointed out. By installing sandblasted glass in these places, you can avoid being seen from the outside and also add features such as lighting and beauty to these places.

Sandblast glass, with its wonderful features, provides you with countless possibilities and benefits. Among these features, we can mention high impact resistance, low light reflection coefficient, privacy protection, thermal shock resistance, and the possibility of easy installation. These features have made sandblasted glass popular in the market.

Unlike transparent glass, the use of sandblasted glass comes with various features that are very attractive to users. One of these characteristics is the design and color on the glass, which gives a lot of variety and visual beauty to the glass. To produce sandblasted glass, a matting process or water is used for glass. In this process, parts of the glass surface are covered and made opaque by using tools such as sand and air flow.

Using sandblasted glass in private environments has many advantages. Among these advantages, we can mention the privacy of users, creating beauty and visual appeal, preventing the hope of winning spaces, controlling light and heat, as well as preventing sound disturbances. Although it is visually appealing, sandblasted glass is also considered as a safety element because its opaque effect meets people’s basic needs to protect their privacy.

Other uses of sandblasted glass include interior and exterior decoration such as doors, windows, parquets, and even office interior design. Due to its unique characteristics, this type of glass is used to create beautiful and attractive spaces using innovation and creativity. Sandblast glass also adds to the beauty and classic effect of certain environments and creates a pleasant feeling for users.

Float glass:

Float glass or flat glass is the first type of glass produced. This type of glass is produced and supplied in different thicknesses from 2 mm to more than 20 mm. Commonly, thicknesses of 4-8 mm are used in buildings.

Due to its special production method, flute glass is often without waves and bends, for this reason it is widely used in buildings and especially windows.

Float glass can be used in a primary form or in a processed form and increase new functions.

Electric frosted glass:

The new type of glass is electric frosted glass or smart glass. These types of glasses are often laminated and have all the features of laminated glass. In addition, with the PDLC coating between the two glasses, they have the possibility of becoming opaque or transparent in a fraction of a second using electric current.

Frosted glass is used to create privacy. And they can play a significant role in new building designs.

Fireproof glass or Pyrex:

Pyrex glass or fireproof glass has a high resistance to heat. They are usually used as laboratory and kitchen utensils or in front of wall heaters and ovens.

Double-glazed glass:

Double-glazed glass consists of two simple and sometimes colored layers that are placed parallel to each other and their edges or seams are sealed. The space between them is filled with drying materials such as silica gel, or in some cases, a vacuum is created between the two layers.

This type of glass, which is heat, cold and sound insulating, is used in many buildings such as airports, hotels and hospitals.

Double-glazed glass consists of gluing one or more parallel panes of glass together to form an impermeable unit. Argon gas is injected between these two glasses. Argon gas injection in double-glazed windows is very practical and important.

Argon gas, in addition to reducing the thermal conductivity between the two panes of the UPVC double-glazed window, prevents more heat loss by reducing the amount of convection in the space between the two panes. The concentration of argon gas in double-glazed windows and doors should be more than 75% in order to have the required quality.

Production steps of double-glazed glass:

Automatic cutting of glasses in the right size with automatic machines

Bending of aluminum molds

The aluminum frames used in the production process of UPVC double-glazed windows and doors are made of a special alloy with a wide variety of colors.

They can be easily bent.

Injection of moisture absorbent material

The injection of moisture-absorbing materials is done according to the following conditions:

The amount of material injection is done by the device.

Desiccant injection is done in closed conditions and evacuated from the air so that the ability to absorb air moisture between the two walls of the glass remains for this material and this material is not saturated before use.

Washing double-glazed glass using special detergents and distilled water

Washing double-glazed glass using special detergents and distilled water

Aluminum frame mounting system

Glass frosting methods:

The following methods can be mentioned among the most important and widely used methods for producing frosted glass:

Use frosted glass stickers

Use of glass frosting spray

Matting by sandblasting method

Matting through acid washing

Features of the glass facade:

Increasing building security and safety

Sound controller

Prevent the passage of ultraviolet rays

Efficiency of solar energy

Variation in color

The glass facade has less dead load than other windows

Reduce costs

Nano or smart glass:

Nano glass is one of the types of smart glass that has many fans today and is used in many industries. Water repellency and impact resistance are just a few examples of these features that make many designers and manufacturers welcome it. If you are planning to buy and use nano glass, read this article to learn more about the nature and features of this modern product.

This type of glass is easily available today. The reason why this product is named nano is that on the surface of this glass, a nano-scale porous structure has been created, which makes it resistant to scratches and has hydrophobic properties. For this reason, it is also known as hydrophobic nano glass. These features make nano glass different from ordinary glass and other types of glass and find many applications.

What is the difference between nano glass and nano glass?

You might imagine that nano glass is the same as nano glass; But these two products are completely different. Of course, both have hydrophobic properties; This means that the water is not spread on them, but it slides on the surface of the glass in the form of drops and moves away. But they differ from each other in the following cases.

Nano glass is the same as ordinary glass on which a layer of hydrophobic coating is placed. This layer equips the glass with water-repellent properties. While nano glass is the glass itself that has a nanometer porous structure from the beginning of production, and as a result, it has hydrophobic properties.

The only special feature of nano glass is its hydrophobicity; While the advantages of using nano glass are many and being hydrophobic is just one of them.

Nano glass is used only in cases where the property of being hydrophobic is considered; But nano glasses are used in various industries. For example, nano-ceramic glass is used in the automotive industry.

How to produce nano glass

Nano silica particles are the main component of nano glass. For this reason, in the first stage of production, when the raw materials must be prepared, silica and other minerals are well powdered and then combined with each other. The combined materials are transferred to very high temperature furnaces and melted in order to become liquid and malleable.

When the materials reach the melting temperature, they are immediately cooled during a special process. The same work causes the molecules to change shape and become solid in a different form from their original form and take on the appearance of glass.

The same work causes the molecules to change shape and become solid in a different form from their original form and take on the appearance of glass. Finally, when the glass gets its original shape, it goes through the final stages of its production with the help of turning or other processes.

Types of nano glass

There are many types of nano glass, each of which brings special features to users. Getting to know the types of this product can help you make a better choice and choose the right option for your desired location. These examples are:

Self-cleaning glasses:

Self-cleaning glass is one of the types of nano glass, which is made of titanium dioxide particles. The presence of this substance makes it so that no stains sit on it, and on the other hand, it also has antiseptic properties.

Titanium dioxide particles are drawn as a layer on the glass to cover the depressions of the glass surface and the glass has a completely smooth surface. This will prevent the water droplets from entering the recesses and sliding off the glass in contact with the self-cleaning glass. This feature also happens to oil droplets. As a result, the glass is neither stained nor sticky.

Anti-reflective glass:

Another type of nano glass is anti-reflective glass. Another type of nano glass is anti-reflective glass. This allows the maximum amount of light to pass through the glass, and in addition to creating beauty, it is also useful for saving energy and reducing electricity consumption.

Sunscreen Glass:

Nano sunscreen glass is produced in different ways, the most famous of which is photochromic smart glass. In the design of most buildings, anti-sun glasses are used to prevent too much light from entering the environment; Because they can easily manage the amount of light passing through.

Fireproof glass:

To produce this nano glass, silica particles are placed in the middle of two glasses. In addition to making the building resistant to fire in this way, it is possible that ultraviolet and infrared rays will not pass through it, thus saving excessive energy loss.

What are the uses of nano glass?

Depending on their type, nano glasses are produced for different purposes and have many applications. These glasses are used in many industries and can meet many needs. Industries such as automobile manufacturing and construction are at the top of these cases.

Nevertheless, the use of this widely used product is also seen in the electronics and disinfection industries. Of course, some materials such as concentrated nano glass can turn normal surfaces such as the car body into a hydrophobic surface. Other uses of nano glass in industry include:

The automotive industry: When nano particles are used in car windows, not only the light reflection is reduced and safety is increased, but also the impact resistance is increased. The car glass nano label is one of the things that is helped by this technology.

electronics industry: Sensors, transistors, and even diodes are among the things that can speed up electronic devices with the help of nano particles, and as a result, they are more effective.

Medical industry: Nano glass is also used to make contact lenses in ophthalmology. This product gives the lens anti-viral and anti-bacterial properties and prevents it from getting infected.

Construction industry: These glasses are used in building windows. In this way, they are used as thermal and sound insulation. Nano building glass is one of the things that is used in this industry and has many advantages.

Nano glass glue: Another application of this industry is that it can stick on any surface and turn it into a nano surface.

Transportation and storage of glasses:

The transportation and storage of glass is such that it must be done carefully so that problems such as filling and breaking the glass do not occur.

Glass cups should be covered with cloth and tightly packed and placed in strong wooden boxes.

Papers should be placed between the two glasses to prevent the two glasses from touching each other.

The specifications of the glass, such as the factory that made the glass, the thickness of the glass, the dimensions of the glass, the number of glasses in the package, and other important features should be written on the packaging boxes in which the glass is located.

The glasses that are large in size should be transported with special glass transporters so that they don’t get damaged.

To facilitate the transportation of glass cups, they use Langen Dorf transporters.

Cleaning the glass:

Glass is one of the main materials in any building, without which it can be said that construction is impossible. However, do not forget that cleaning the glass is the main factor that you need for beauty, and of course it may be simple in appearance; But it needs to be done in principle. However, do not forget that cleaning the glass is the main factor that you need for beauty, and of course it may be simple in appearance; But it needs to be done in principle.

method:

- Prepare the necessary ingredients. These materials include cloth, spray and sponge.

- Remove stains, dust or any contaminating object on the glass.

- Wet the stain on the glass with a few puffs of glass cleaner spray and let it sit for a while.

- Remove the stain with a sponge.

- Apply cleaning solution to the entire glass.

- Wipe the glass with a clean cloth.

If the result is still not satisfactory, repeat from number 3 onwards.

Construction Glass Industry

Kavian Jaam Glass Industrial Group

Media error: Format(s) not supported or source(s) not found

Download File: https://irkgc.com/wp-content/uploads/2024/06/01_eftetahiye.mp4?_=2

بدون دیدگاه